Engineering Solutions

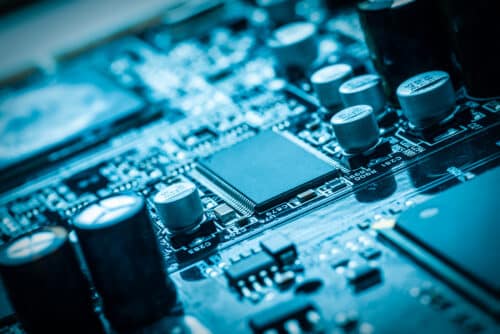

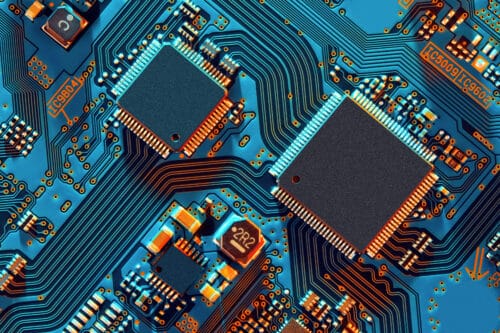

At DIVaero, we are experts in engineering, designing, and re-designing sophisticated electronic modules or assemblies. Working closely with our customers to develop new products or bring obsolete products back to life keeps our engineering team abreast of new technologies and ever-evolving manufacturing techniques. Using a multi-disciplined approach and many decades of hands-on experience, DIVaero has fine-tuned the process of managing the detailed program requirements for new product introductions (NPI) and seamlessly transitioning to prototype and production methodologies. Our systems and processes are purposefully designed to accommodate the rigorous technical and quality requirements of our high technology customers.

Assembling a staff of qualified and experienced electrical/hardware, software, and mechanical engineers with hands-on experience in both circuit board fabrication and assembly was a calculated, intentional evolution. Our solutions can incorporate circuit design, PCB layout, software and firmware development, mechanical design, prototyping, test fixture development and methodology, electronic assembly, and systems integration/box build. We utilize powerful design automation tools such as SolidWorks, Altium and AutoCAD to generate Gerber artwork, 3D models, solids models, and product verification and validation.