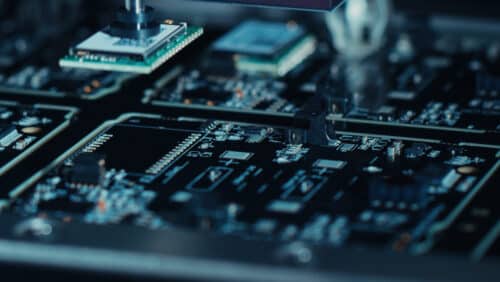

Custom PCB Assembly Solutions for Military and Aerospace Electronics

DIVaero leads the way in Custom PCB Assembly through a powerful combination of innovation, strategic investment, advanced quality systems, and decades of engineering experience. Our expert team delivers end-to-end PCB manufacturing services, including box build assembly, functional testing, conformal coating, and wire harness integration; all tailored to meet your exact project specifications. From initial concept and low-rate initial production (LRIP) to full-scale manufacturing, DIVaero ensures high-reliability electronics and military-grade PCB solutions that exceed performance standards across every phase of production.

Capabilities

To ensure unparalleled quality results, we leverage leading technology and highly skilled personnel to work closely with you. We work with you through every process stage – from design concept to full system integration – using cutting-edge technologies and state-of-the-art facilities. With our capabilities, we can provide you with various PCB assembly services:

Military & Aerospace PCB Prototyping, Validation, and LRIP Services

We provide high-precision PCB prototyping, validation, and Low-Rate Initial Production (LRIP) services specifically engineered for military and aerospace applications. Our advanced capabilities support the rapid development of mission-critical electronics, ensuring every circuit board meets the highest standards for reliability, performance, and regulatory compliance.

With integrated engineering support and detailed design feedback, we help defense and aerospace contractors accelerate development cycles while maintaining full control over quality and documentation. Whether you’re validating a new aerospace circuit board design or preparing for defense-grade LRIP PCB production, our team brings unmatched attention to detail and technical expertise to every build.

Production Runs

DIVaero is your trusted partner for prototype and validation runs of PCB assemblies. Whether you’re testing a new design or preparing for low-volume production, our team delivers the expertise and speed you need to move forward with confidence.

Why Choose DIVaero for PCB Prototypes?

- Onsite Engineering Support: Get immediate design feedback during the manufacturing process, reducing turnaround times and minimizing costly revisions. Our engineers work directly with your team to ensure designs translate seamlessly into production.

- Serialization & Traceability: Every prototype and validation run includes the same serialization and traceability standards as our full production builds, ensuring consistency, quality, and compliance without unnecessary delays.

- Reporting Options: We provide a range of documentation options tailored to your needs, ensuring clarity and compliance throughout the process:

- General First Article Reports: Standard reporting to confirm design accuracy and production readiness.

- AS9102 FAIR (First Article Inspection Reports): Comprehensive inspection reports meeting AS9100/AS9102 standards for aerospace and defense applications.

- Engineering Evaluations: Detailed assessments designed to identify opportunities for optimizing production efficiency and reducing costs.

Prepare your PCB assembly for production success. Our prototype and validation build services are designed to set your product up for seamless transition into full-scale production. With quality control and expert engineering support, DIVaero helps you stay ahead in your development cycle.

Complex SMT

PCBs are mounted directly onto the surface using Surface Mount Technology (SMT). DIVaero specializes in custom manufacturing solutions tailored to each customer’s needs. Delivering complex SMT through progressive technology combined with automated assembly lines is something we take great pride in – no detail is overlooked! As PCB assemblers, we can do the following for you:

- BGA, LGA placement/replacement: Our specialized placement or replacement tool offers maximum BGA or LGA chip mounting precision. We use advanced soldering machines controlled by durable cameras providing the highest accuracy, ensuring that your components are perfectly placed at the correct positions with a tightly joined mount. Our high-tech capabilities and years of expertise guarantee excellent results every time.

- Any part size in current commercial use: Our exclusive SMT technology features a versatile double-placed product placement system, giving your projects the added dimension that comes with electronic assembly expertise. Our machines can be programmed to adjust easily to your specifications with each project for superior accuracy.

Selective Soldering

In military and aerospace applications, solder joint integrity is critical to long-term reliability. Our selective soldering systems provide the process control and precision required to meet IPC Class 3 and MIL-STD workmanship standards.

Key Technical Advantages Include:

- Thermal Management: Programmable heating profiles minimize risk of thermal stress, protecting temperature-sensitive components and multilayer assemblies.

- Process Repeatability: Servo-controlled motion and closed-loop process monitoring ensure consistent solder joint geometry and wetting quality across every production run.

- Flux Control: Automated, localized flux deposition eliminates contamination risk while ensuring proper joint formation.

- Nitrogen Environment: Inert atmosphere capability reduces oxidation, improving wetting action and overall joint reliability.

- Design Flexibility: Selective soldering enables mixed-technology boards to be manufactured without the need for full wave soldering, reducing masking requirements and rework.

Conformal Coating

Precision Robotic Conformal Coating In-House

At DIVaero, we utilize advanced in-house robotic conformal coating systems to deliver consistent, high-quality protection for printed circuit boards and electronic assemblies. Our fully programmable selective conformal coating and dispense system is a multi-purpose platform designed for precision, repeatability, and efficiency in automated material application.

Equipped with multiple spray and dispense valves, our system supports a wide range of coating materials, including:

- Silicones

- Acrylics

- Urethanes

- Epoxies

- Solvent-based, water-based, and 100% solids coatings

Outsourced Parylene Coating for Extreme Environments

For projects requiring ultra-thin, high-performance protection, DIVaero also offers outsourced parylene coating services.

Parylene is applied through a unique vacuum deposition process that forms a pinhole-free, conformal layer over every surface – ideal for sensitive electronics and aerospace components. This coating delivers:

- Exceptional resistance to chemicals, solvents, and aviation fuel

- Protection against moisture, gases, fumes, and corrosion

- Reliable performance in harsh aerospace environments, including extreme temperatures and radiation exposure

Box Build

At DIVaero, our box build assembly services are engineered to meet the extreme demands of the military and aerospace industries. From rugged avionics enclosures to complex electronic subsystems, we deliver fully integrated assemblies with the reliability, traceability, and security required for mission success.

Military and aerospace assemblies must operate flawlessly under extreme temperature, shock, vibration, and EMI conditions. Our team collaborates with you to ensure assemblies meet or exceed whatever standards your product requires.

Testing / Test Development

At DIVaero, we offer in-house and external testing solutions to ensure your products meet the highest standards of safety, compliance, and reliability.

Whether following your test plan or providing a turnkey solution, we validate that your product performs before it ever sees the field.

In-House Testing Capabilities Include

- Power-up, functional, and burn-in testing

- Tests on customer-supplied or DIVaero-developed test stands

- Custom test fixtures, systems, and software

- Test Documentation

External Testing Services

DIVaero manages certified testing through trusted labs, including:

- EMI/RFI, EMC, and MIL-STD testing

- Environmental, vibration, and stress screening

We coordinate all aspects and ensure your results meet your requirements or standards.

Custom Test Development

Our engineers develop:

- Test stands, harnesses, and automated equipment

- Custom software (LabVIEW, Python, etc.)

- Full documentation and support

Documentation / Reporting / Traceability

At DIVaero, all builds follow the same AS9100-certified processes for serialization, traceability, and documentation. Every board is serialized and scanned at each labor center, with traceability from material receipt through final shipment.

We Can Provide:

- AS9102 FAIRs & General First Article Reports

- Test Documentation

- Engineering Evaluations for process improvement

- Custom Documentation Packages to meet program needs

Our tracking and reporting support compliance, quality, and confidence for every aerospace and defense project.

Your one-stop shop for all your PCB assembly needs

At DIVaero, we offer comprehensive PCB assembly solutions tailored to the high standards of the aerospace and defense industries. Whether you’re developing a new PCB design or working from an existing layout, our precision-driven approach ensures enhanced performance, quality, and reliability.

From prototyping to full production, our end-to-end PCB assembly services are designed to meet demanding technical requirements while maintaining traceability and compliance with AS9100 standards.

Why Choose DIVaero for PCB Assembly?

- Turnkey PCB assembly from concept to completion

- Expertise in aerospace, defense, and high-reliability sectors

- Full support for design, testing, and traceability

- Scalable solutions for prototypes, validation, and production runs

Contact DIVaero today to get started with trusted, high-quality PCB assembly services.